Frustrated with edge intermediate sanding?

Who hasn’t experienced the laborious and time-consuming wood sanding of formatted and milled edges? Even with large workpieces, ARMINIUS users can tackle this step on their machines in just a few minutes. With these products it’s all about clamp and go.

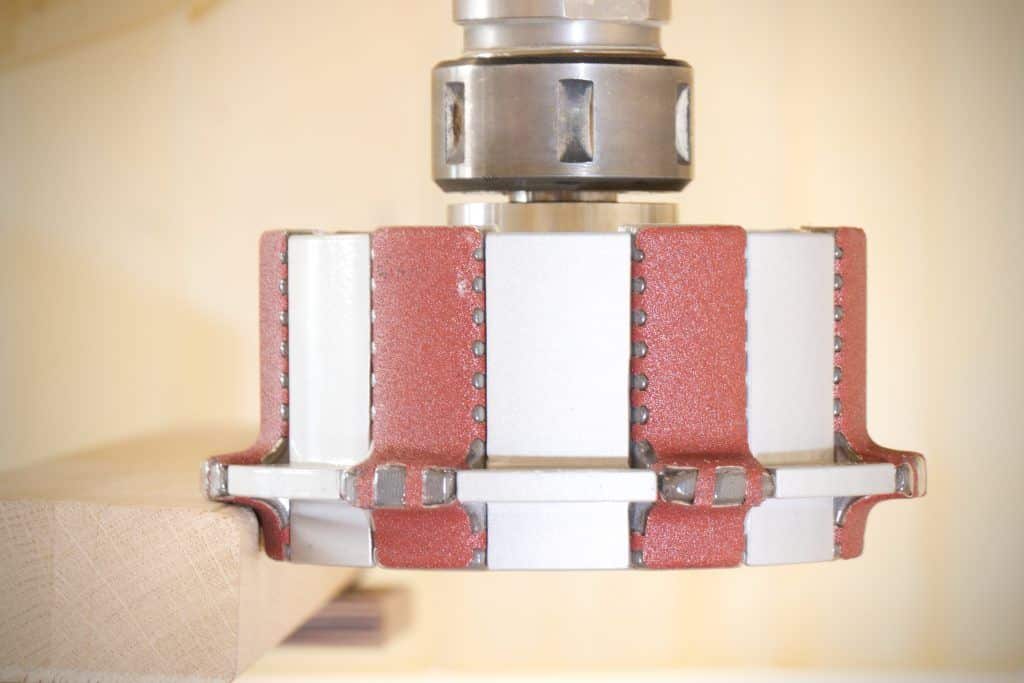

With their new Standard edge sanding tool, ARMINIUS now meets the request of many new users for a straightforward standard solution for processing traditional radii and bevels.

For a Smart Throughfeed

During milling, the raised wood fibers on the workpiece are eliminated. The removal of these wood fibers at the edge happens in the same pass. With just one setup, both the milling and sandingprocesses are completed. Without any further finishing, the workpiece moves on to the next stage of processing. This results in a uniform surface, ensuring excellent adhesion and color stability.

The user benefits from absolute procedural coherence. Thus, the users always processes their workpiece with the desired final grit. Throughout the entire service life, they can rely on the planned processing time and consistent surface quality.

The “Click-fix” Plug System

The robust tool design not only provides the user with a durable tool for decades. The Standard edge sanding tool also comes with an innovative plug system for easy and secure handling. The consumable parts consist of ready-made caps that can be replaced in just a few seconds using the new “Click-fix” plug system. “Click-fix” enables extremely fast tool changes.

The Grit of the Sanding Caps

With the very long service life of the supplied consumables, there is no need for readjustment. The sandingcaps are available in all common grits. These innovative sanding elements prevent tear-outs and reliably compensate for tolerances at the edge. They achieve maximum sanding effectiveness by maintaining a constant sanding pressure on the surface.

One Tool for All Edges

The new edge sanding tool is a versatile product for all edge processing and is designed for both radii between 1-10 mm and 45° bevels. It can be used for processing all workpieces up to a height of 45 mm.

The Development Path

The goal for German tool manufacturer ARMINIUS was primarily to simplify standard edge processing for users. Thisimprovement towards easier usability is greatly appreciated by ARMINIUS customers. Through systematic effort, a new mature standard tool solution has thus been introduced to the market. “The goal was to combine a greatquality standard with the highest technological level to provide the customer with a significant economic advantage,” says Engineer Karsten Kramer, Development and Design Manager at ARMINIUS.

The series also includes the Standard groove sanding tool. Both new developments are operableforward and reverse. They can be used on all common processing machines. The new standard tools are made for sanding solid woods as well as veneers and composite materials such as MDF, HDF, or plywood. They complement the extensive portfolio of the tool manufacturer ARMINIUS. The specialist in high-quality sandingtools and brushes has been developing project-specific tools for the wood industry at their headquarters in Germany for over 60 years.

Source: holzrevue.ch